Suzhou jinruier electric furnace main steel strip annealing furnace processing!

- Index

- About us

-

Product

- Stainless steel annealing furnace

- Tubular annealing furnace

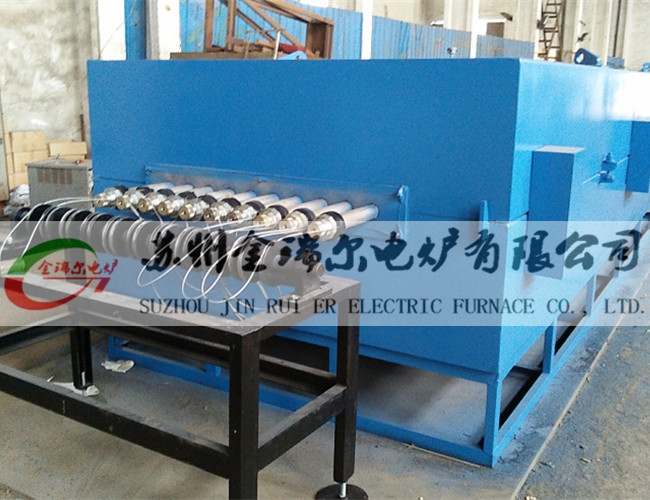

- Idler type annealing furnace

- Copper annealing furnace

- Bell type annealing furnace

- Mesh belt annealing furnace

- Trolley type annealing furnace

- Well type annealing furnace

- Gas furnace

- Aluminum alloy heat treatment furnace

- Rotary furnace

- Strip continuous annealing furnace

- Box furnace and oven

- Transverse magnetic furnace, amorphous annealing furnace

- Silicon steel sheet core annealing furnace

- Electric furnace accessories

- Stainless

- Tubular

- Sales

- News

- Contact Us