Some customers may ask the following questions when steel tube annealing furnace is used for steel tube heating process, for example:

1. Will there be "black core" when steel pipe is heated by steel pipe weld annealing furnace?

A: there are many reasons for the "black core". Generally, the "black core" is produced only when the heating time is not enough or the power selection of the heating equipment is problematic. The solution to this situation is to increase the power, extend the heating time or raise objection to the selection of equipment frequency.

2. Can steel pipe push bending be done by steel pipe weld annealing furnace?

A: the function of steel pipe weld annealing furnace is to heat the steel pipe instantaneously. The normal operation of the equipment is "heating". In addition, if you want to do "push bending", "hot pressing", "quenching" and other processes, you must match the relevant equipment, such as push bending machine, press, quenching machine and other relevant mechanical equipment, to match the heating equipment.

3. Is it easy for the equipment to break down when the annealing furnace is used to heat the steel pipe?

A: as a manufacturer, we are very responsible to tell you that there are times when the equipment fails. It depends on the after-sales service of the manufacturer? If you buy our equipment, we guarantee to reach your factory for repair within 8 hours. As an industry brand, we value service more than sales.

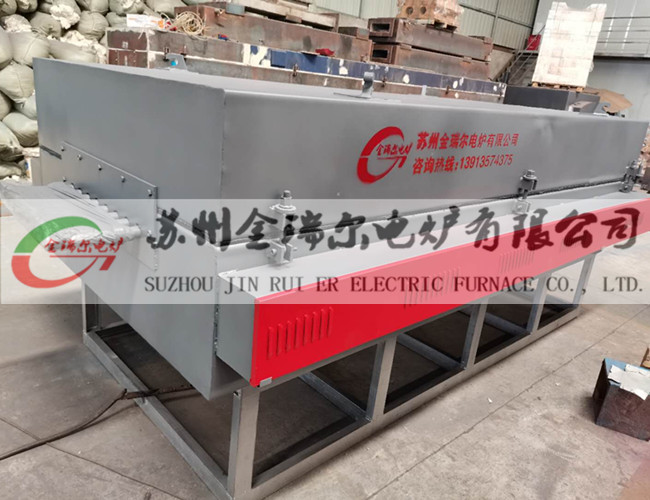

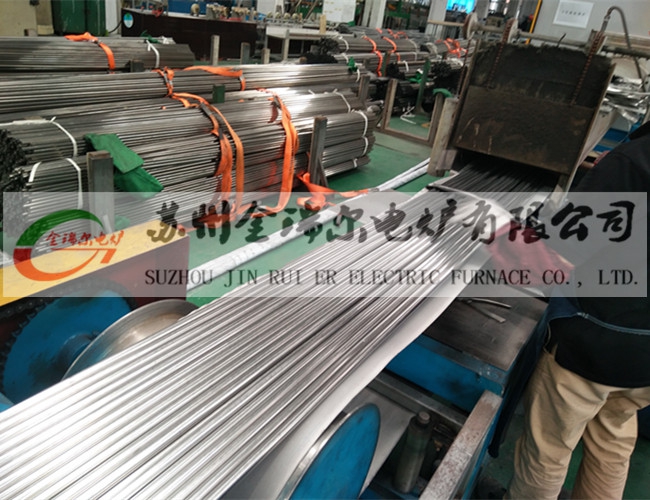

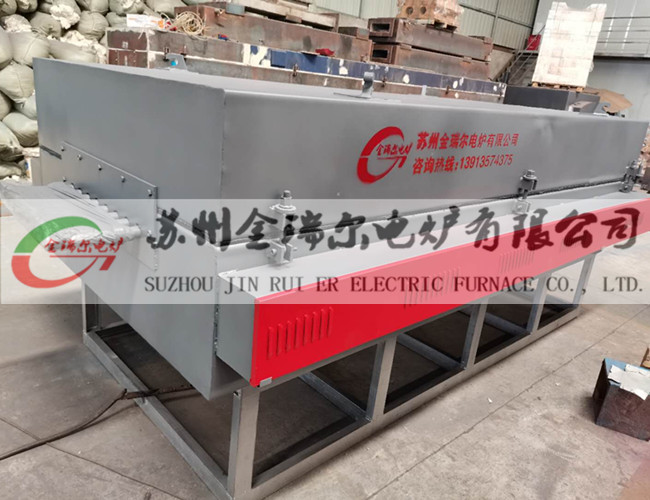

The working principle of steel pipe weld annealing furnace: high frequency and large current flow to the heating coil (usually made of copper tube) which is wound into ring or other shape. Thus, a strong magnetic beam with instantaneous change of polarity is generated in the coil. When a heated object such as metal is placed in the coil, the magnetic beam will penetrate the whole heated object, and a large eddy current will be generated in the opposite direction of the heating current inside the heated object. Because there is resistance in the heated object, it will produce a lot of Joule heat, which makes the temperature of the object rise rapidly. Achieve the purpose of heating all metal materials.

The high-power induction heating device of steel pipe weld annealing furnace has been using electron tube as switch device for many years. Due to the short life of electron tube, low efficiency (50% - 70%) and poor load stability, the output voltage of inverter appears intermittent oscillation (voltage source inverter) during light load operation, so it is imperative to use IGBT semiconductor devices to replace electron tube devices in high frequency and high power occasions. The induction heating device using IGBT semiconductor device has high efficiency and simple circuit. It is easy to manufacture and use. IGBT high-power induction heating power supply has the advantages of fast heating, easy control, less decarbonization and reliable process quality. So using IGBT to realize high power induction heating power supply is a wise choice. The KS series and KP series high frequency induction heating control boards produced by our company have the advantages of digital trigger, debugging free, low pulse distortion, strong anti-interference ability, centralized control, fast dynamic response and multiple state protection indication.