What are the requirements of stainless steel annealing for stainless steel bright annealing furnace

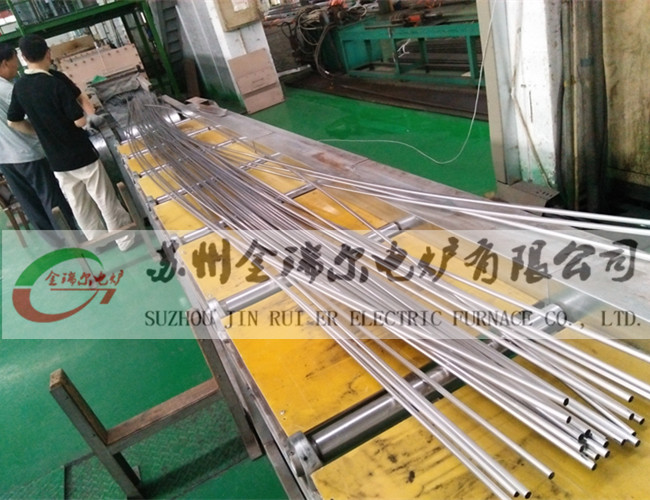

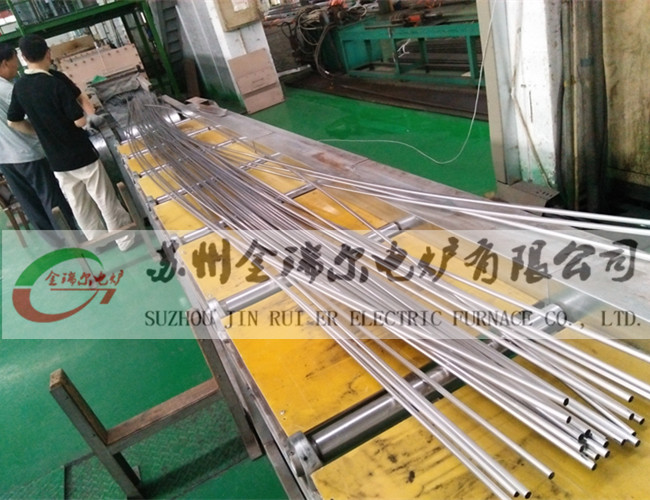

Stainless steel continuous bright annealing furnace is mainly used for heat treatment of stainless steel tube or stainless steel products (such as stainless steel elbow, stainless steel stretching parts, tableware, etc.) in protective atmosphere. Customers have different requirements for metallographic structure after bright annealing, so the heat treatment process is different.

The typical heat treatment process of 300 series austenitic stainless steel is solution treatment. In the process of heating, the carbides are dissolved in austenite, heated to 1050 ~ 1150 ℃ for a short period of time, and then rapidly cooled to below 350 ℃ to obtain supersaturated solid solution, that is, uniform unidirectional austenite structure. The key of this heat treatment process is rapid cooling, which requires a cooling rate of 55 ℃ / s and a rapid re precipitation temperature zone (550 ~ 850 ℃) after carbide solid solution. The holding time should be as short as possible, otherwise the grain size will be coarse and the surface finish will be affected.

The temperature of 400 series ferritic stainless steel is relatively low (about 900 ℃), and the annealed softening structure is obtained by slow cooling.

Duplex stainless steel has the characteristics of both ferritic stainless steel and austenitic stainless steel, so the requirements for bright annealing furnace are relatively high.

Therefore, no matter which series of stainless steel has great difference in heat treatment system, in order to obtain qualified metallographic structure, the cooling section equipment of bright annealing furnace is required to have a lot of room for adjustment. Therefore, the strong convection cooling is often used in the cooling section, with three to four cooling sections, which can adjust the water flow independently. Moreover, the muffle tank must have good air tightness and be isolated from the outside air, so as to achieve neither air leakage nor water leakage.

-------------------------------------------------

Suzhou jinruier Electric Furnace Co., Ltd. mainly produces: steel tube annealing furnace, bell type furnace, trolley furnace, well type furnace, stainless steel bright annealing furnace, natural gas annealing furnace, mesh belt furnace, aluminum alloy heat treatment furnace, spheroidizing furnace, quenching furnace, industrial electric furnace, oven, bright annealing furnace, vacuum annealing furnace, electric furnace accessories, etc.