Characteristics and advantages of annealing furnace:

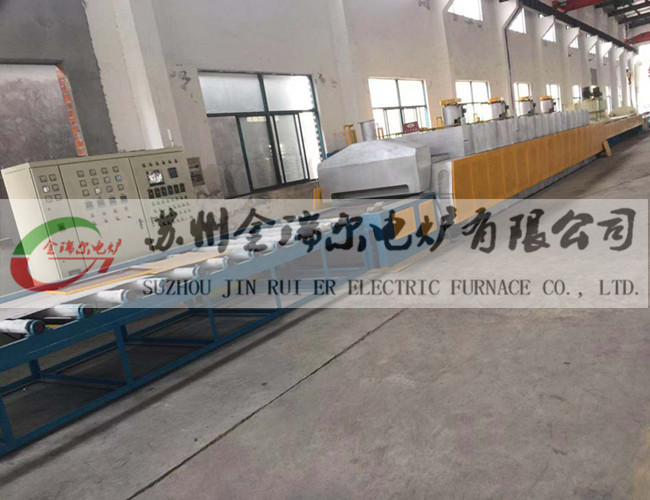

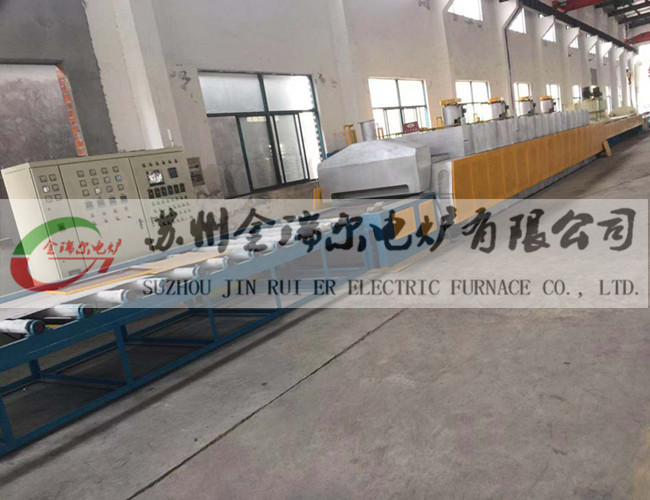

The mesh belt annealing furnace uses the continuous running mesh belt to transport the workpiece, through the temperature controlled heating zone, so as to achieve the purpose of tempering the workpiece.

It has the following characteristics and advantages: the mesh belt is made of high strength stainless steel wire, which has long service life; the transmission mechanism is simple and reliable, and the mesh belt speed is stepless adjustable; the forced circulation fan with large impeller is used to speed up the air flow speed of the furnace and improve the furnace efficiency It has high heat transfer efficiency and uniform furnace temperature; it is convenient to replace the electric heating elements without removing the furnace top and shell; the furnace lining is made of aluminum silicate fiber cotton, which has good thermal insulation performance; the high-precision instrument is adopted, which has reliable performance and convenient operation. This furnace is especially suitable for the batch production of various standard parts, bearings, bicycle parts, hardware, textile parts, etc. It can form automatic assembly line with mesh belt quenching furnace and cleaning machine. Power 20-90kw, rated temperature 600 ℃.

Purpose: suitable for tempering of chain, standard parts, bicycle parts and tools.

Characteristics and advantages of annealing furnace

The creation and development of trolley type annealing furnace plays a very important role in human progress. In the Shang Dynasty, China had a relatively perfect copper smelting furnace, with a furnace temperature of 1200 ℃ and an inner diameter of 0.8m. In the spring and Autumn period and the Warring States period, people further grasped the technology of improving furnace temperature on the basis of copper melting furnace, and thus produced cast iron.

In 1794, the world presented a straight Cupola for melting cast iron. Later in 1864, French Martin used the principle of Siemens regenerative furnace to create a steel-making open hearth furnace heated by gas fuel. He used the regenerator to preheat the air and gas at high temperature, so as to ensure the temperature above 1600 ℃ required for steelmaking. Around 1900, the power supply was gradually sufficient, and various resistance furnaces, electric arc furnaces and cored induction furnaces were used.

In 1950s, coreless induction furnace was developed rapidly. Later, an electron beam furnace was introduced, in which the solid fuel was impacted by electron beam, which could strengthen the surface heating and melt high melting point materials. The earliest furnace used for casting heating is hand forging furnace. Its working space is a concave groove filled with coal. The air for burning is supplied from the lower part of the groove, and the workpiece is buried in the coal for heating. This kind of furnace has low thermal efficiency and poor heating quality, and can only heat small workpieces. Later, it will be developed as a semi closed or fully closed chamber furnace built with firebrick, which can use coal, gas or oil as fuel, and electricity as heat source, and the workpieces will be heated in the furnace.

For the convenience of heating large workpieces, a trolley type furnace suitable for heating ingots and billets is presented, and a well type furnace for heating long rods is also presented. After the 1920s, various mechanized and active furnace types which can improve furnace production rate and working conditions appeared.

Along with the development of fuel resources and the progress of fuel conversion technology, the fuel of trolley type annealing furnace has gradually changed from solid fuels such as lump coal, coke and pulverized coal to gas and liquid fuels such as producer gas, city gas, natural gas, diesel oil and fuel oil, and various incineration equipment suitable for the fuel used has been developed.

The structure, heating technology, temperature control and furnace atmosphere of trolley type annealing furnace will directly affect the product quality after processing. In the casting furnace, increasing the heating temperature of the metal can reduce the deformation resistance, but too high temperature will cause grain growth, oxidation or overburning, which seriously affects the quality of the workpiece. In the process of heat treatment, if the steel is heated to a certain point above the critical temperature and then cooled suddenly, the hardness and strength of the steel can be improved; if the steel is heated to a certain point below the critical temperature and cooled slowly, the hardness of the steel can be decreased and the toughness can be improved.

In order to obtain the workpiece with accurate scale and smooth appearance, or to reduce metal oxidation to protect the mold and reduce machining allowance, various kinds of less or no oxidation heating furnace can be selected. In an open flame furnace with less or no oxidation, the recovery gas is produced by incomplete burning of fuel, in which the oxidation burning rate can be reduced to less than 0.3% by heating the workpiece.

Controlled atmosphere furnace is a kind of artificial atmosphere, which can be used for gas carburizing, carbonitriding, bright quenching, normalizing, annealing and other heat treatment, so as to change the metallographic arrangement and improve the mechanical properties of the workpiece. In the movable particle furnace, the burning gas of fuel or other fluidizing agent applied externally is forced to flow through the graphite particle or other lazy particle layer on the hearth. The workpiece buried in the particle layer can complete the intensified heating, and can also carry out carburizing, nitriding and other non oxidizing heating. Using molten salt as heating medium in salt bath furnace can prevent oxidation and decarbonization of workpiece. Smelting cast iron in cupola is usually affected by coke quality, air supply method, charge condition and air temperature, which makes it difficult to obtain high quality molten iron. Hot blast cupola can effectively improve the temperature of hot metal, reduce the alloy burning loss, and reduce the oxidation rate of hot metal, so as to produce high-grade cast iron.

With the appearance of coreless induction furnace, cupola is gradually replaced. The melting operation of the induction furnace is not restricted by any grade of cast iron. It can quickly transfer from melting one grade of cast iron to melting another grade of cast iron, which is conducive to improving the quality of molten iron. Some special alloy steels, such as ultra-low carbon stainless steel, roll and steam turbine rotor, need to refine the molten steel from open hearth or general electric arc furnace through vacuum degassing and argon stirring in the refining furnace, so as to further refine high-purity and large capacity high-quality molten steel.

The fuel of flame furnace has a wide history and low price, so it is convenient to tailor according to the circumstances. Adopting a different structure is conducive to reducing the production cost. However, it is difficult to control the flame furnace accurately, causing serious environmental pollution and low thermal efficiency. Electric furnace is characterized by uniform temperature, easy to complete active control and good heating quality. According to the energy conversion method, electric furnace can be divided into resistance furnace, induction furnace and electric arc furnace. The furnace heating capacity calculated by unit time and unit bottom area is called furnace yield. The faster the heating rate of the furnace and the larger the load of the furnace, the higher the yield of the furnace. In general, the higher the furnace yield, the lower the unit heat consumption per kilogram of material. Therefore, in order to reduce energy consumption, full load production should be carried out to improve the furnace production rate as much as possible, and the active share of fuel and combustion air should be adjusted together to prevent excess or lack of air. In addition, the loss of heat storage and heat dissipation of furnace wall, heat loss of water cooling components, radiation heat loss of various openings and heat loss of flue gas taken away from the furnace should be reduced.

The ratio of the heat absorbed by metal or material during heating to the heat supplied to the furnace is called furnace thermal efficiency. The continuous furnace has higher thermal efficiency than the intermittent furnace, because the continuous furnace has higher production rate and continuous operation, the furnace thermal system is in a stable state, there is no periodic loss of furnace wall heat storage, and because there is a preheating section in the furnace, some residual heat of flue gas is because there is a preheating section in the furnace, and some residual heat of flue gas is in the furnace It is absorbed by the cold work pieces of the furnace, which reduces the temperature of the flue gas leaving the furnace. To complete the furnace temperature, furnace atmosphere or furnace pressure active control. Gas is liquefied gas, natural gas, coke oven gas, city gas, converter gas, mixed gas, producer gas, blast furnace gas, etc.