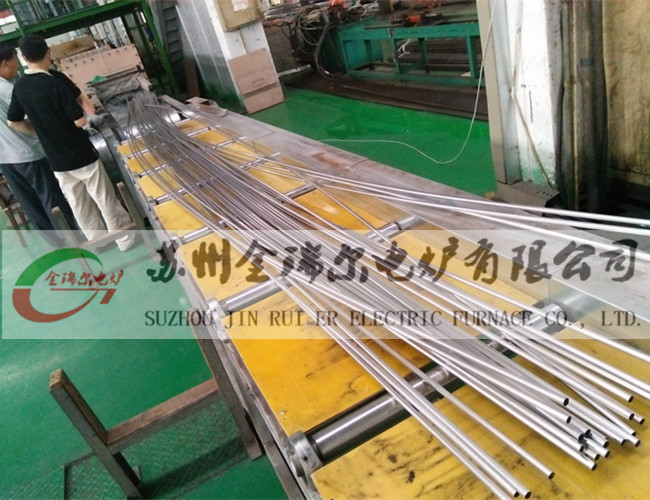

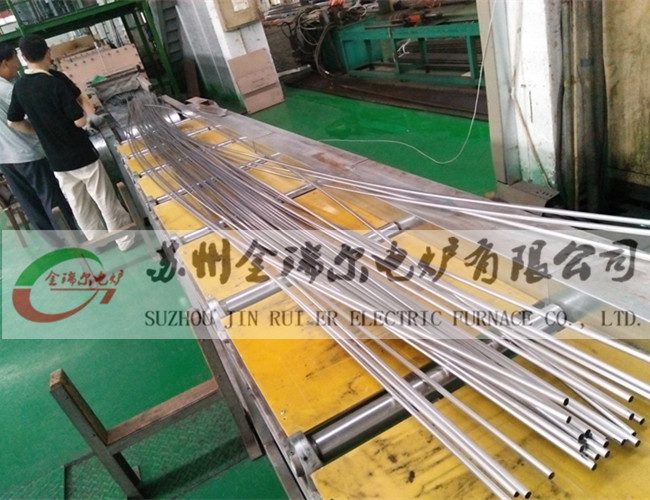

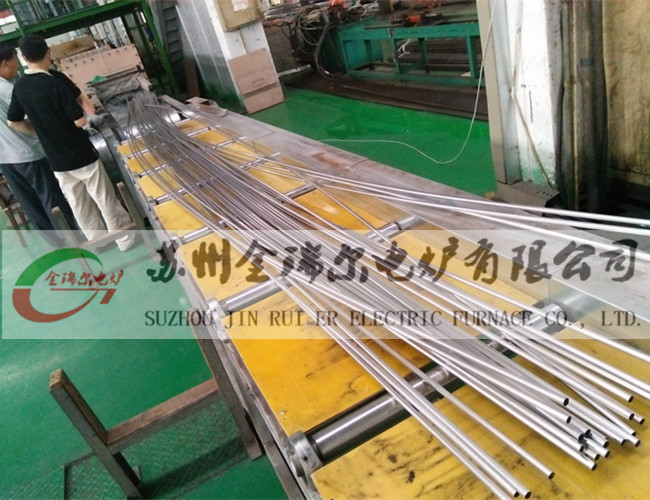

The stainless steel tube bright annealing furnace is mainly composed of heating furnace body, stainless steel muffle tank, conveying steel belt (or mesh belt) and conveying mechanism.

The heating element is made of high-quality and high resistance alloy 0cr27al7mo2, with low surface load, high temperature resistance, quick and convenient installation and maintenance, and no thermal short circuit with the furnace shell. The heating temperature can reach 1100 ℃. The muffle tank is made of high temperature resistant stainless steel plate (310S, 8mm thick) by bending and welding. The outlet is connected with the water cooling device. Under the protection of ammonia decomposition atmosphere, the annealed pipes pass through the muffle tank and are heated. The heating furnace body is of split structure, which is divided into upper cover and furnace base. The upper cover can be opened for easy maintenance.

In order to cool the annealed stainless steel pipe rapidly, the annealed pipe enters the cooling section after passing through the heating section. The cooling section adopts indirect water jacket cooling, and the muffle tank is also set inside and protected by ammonia decomposition atmosphere, so that the annealed pipe is bright and free of oxidation.

Under the action of catalyst, liquid ammonia is heated and decomposed to obtain a mixture of hydrogen and nitrogen with 75% hydrogen and 25% nitrogen, which is flammable. It can burn under the condition of air and release a lot of heat, so it must be strictly controlled in the process of use. In order to ensure the service performance of stainless steel tube bright annealing furnace, it is necessary to inspect the purchased raw ammonia to make all technical indexes meet the standard of furnace liquid ammonia, and the fluctuation value of liquid ammonia filling pressure is required to be within ± 5%, so as to ensure safety. Strictly implement the operation procedures of liquid ammonia decomposition and refining, adjust and monitor according to the specified process parameters, observe the quality of annealed stainless steel pipe at any time, and timely adjust and deal with the problems found, so as to prevent tube quality accidents caused by misoperation. Control the residual ammonia content in the decomposed ammonia.

The causes of excessive residual ammonia in decomposition ammonia are as follows

① The decomposition temperature is too low;

② Overload production;

③ Catalyst activity decline or failure;

④ The reaction tank (furnace) leaks and ammonia gas seeps into the decomposed ammonia.

When the temperature of stainless steel tube bright annealing furnace is raised, before introducing ammonia decomposition atmosphere, nitrogen (oxygen content < 1%) should be sent to blow out the air in muffle tank to prevent explosion. Nitrogen should also be sent when the furnace is shut down. When there is no nitrogen, the method of continuously inputting decomposed ammonia when the furnace temperature is lower than 400 ℃ is adopted, so that there is no air before the furnace temperature reaches the ignition temperature of decomposed ammonia, and the explosion can be effectively avoided. When the furnace is shut down, the input of decomposed ammonia should also be interrupted when the furnace temperature drops below 400 ℃. The special annealing furnace for stainless steel pipe in ammonia decomposition atmosphere can make the surface of annealed stainless steel pipe bright and free from oxidation, and its toughness and plasticity can also be improved, with better corrosion resistance.