Problems and precautions in use of quenching oil in quenching furnace

The allowable and recommended temperature range of quenching oil for all annealing furnace and quenching furnace is specified. Within the specified range, the service temperature can be determined according to the actual situation. The viscosity of the oil can be reduced by properly increasing the oil temperature, so that the quenching cooling capacity of the oil can be slightly improved. If the oil temperature is too high, the cooling capacity will be reduced due to the decrease of the temperature difference between the oil and the workpiece.

High oil temperature leads to rapid oxidative metamorphism, while low oil temperature leads to slow oxidative metamorphism. The circulating cooling system of quenching oil should be kept in good condition to stabilize the temperature of quenching oil in the required range. At the same time, in order to prolong the service life of the oil, the excessive oil temperature should be used less.

Oil pollution and Prevention

The pollution sources of quenching oil include: external pollution, such as oxide scale brought by workpiece, water leaked from cooler and other substances from outside; self pollution, oxidation and deterioration products left in oil that cannot be automatically discharged in use; and residual products after reaction of external pollutants with quenching oil and its pollutants.

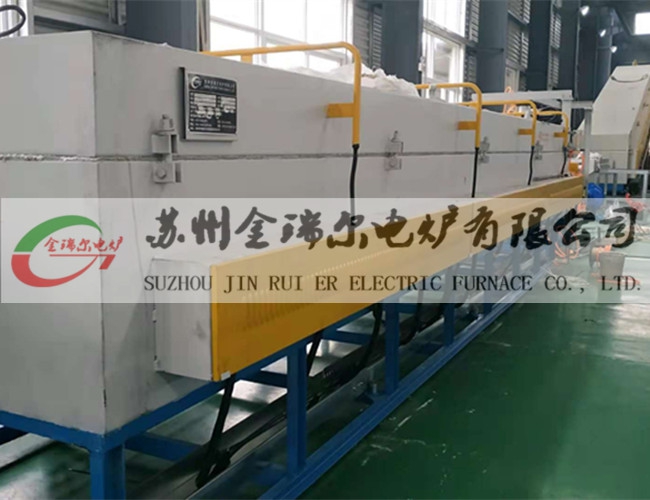

The accumulation of internal and external pollutants will gradually change the color, transparency, viscosity, flash point, residual carbon and acid value of oil. This change process is the metamorphic process of quenching oil. Among the effects caused by the deterioration, the change of oil cooling characteristics and the deterioration of the brightness of the workpiece after quenching are closely related to the heat treatment effect of the workpiece. The change of cooling characteristics often changes the quenching hardness, hardening depth and deformation of the same workpiece. Trolley type annealing furnace

Agitation of annealing furnace for quenched oil steel pipe

Good agitation can avoid high local oil temperature and make the oil temperature in each part of the tank tend to be uniform.

Agitation can increase the relative flow velocity between the workpiece and the quenching oil, thus improving the cooling capacity of the oil.

The setting of stirring device and the mounting method of workpieces should make the workpieces in different parts of the same batch of quenching obtain basically similar oil temperature. Too high or too low relative velocity of some workpieces or parts will have an adverse effect on the uniformity of quenching. Of course, compared with water-based quenching medium, the degree of this effect is much smaller.