The reason why the product from bright annealing furnace is not bright

When the product of bright annealing furnace is not bright, the operator will not be able to judge if he is inexperienced

1. Whether the annealing temperature reaches the specified temperature. Stainless steel annealing furnace generally adopts solution heat treatment, which is commonly known as "annealing". The temperature range is 1040 ~ 1120 ℃ (Japanese standard). It can be observed through the observation hole of the annealing furnace that the stainless steel tube in the annealing zone should be incandescent, but there is no softening and sagging.

2. Annealing atmosphere. Generally, pure hydrogen is used as the annealing atmosphere, and the purity of the atmosphere is more than 99.99%. If the other part of the atmosphere is inert gas, the purity can be lower, but it can not contain too much oxygen and water vapor.

3. Sealing performance of furnace body. The bright annealing furnace should be closed and isolated from the outside air; if hydrogen is used as protective gas, only one vent is open (used to ignite the discharged hydrogen). The inspection method can use soapy water to wipe on the joints of the annealing furnace to see if there is gas leakage. The places where gas is easy to escape are the places where the annealing furnace enters and leaves the pipes. The sealing ring in this place is particularly easy to wear, so it should be checked and replaced frequently.

4. Protection gas pressure. In order to prevent micro leakage, the protective gas in the furnace should maintain a certain positive pressure. If it is hydrogen protective gas, it is generally required to be more than 20kbar.

5. Water vapor in the furnace. On the one hand, check whether the furnace body material is dry, and the furnace body material must be dried for the first time; on the other hand, check whether there are too many water stains left in the stainless steel pipe into the furnace, especially if there are holes in the pipe, do not leak in, otherwise the furnace atmosphere will be completely destroyed.

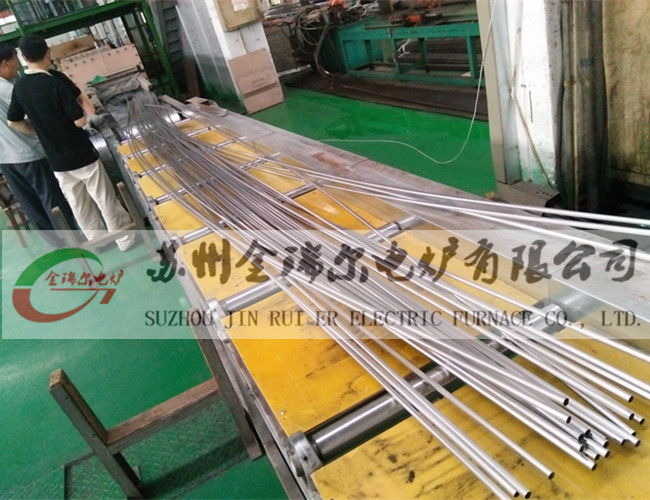

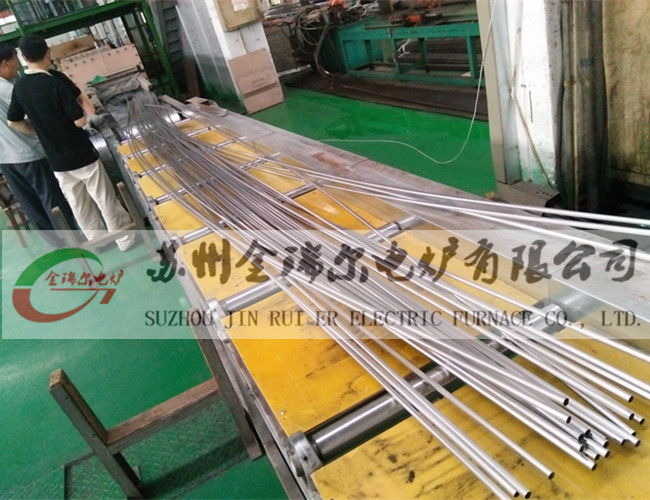

If there are no such problems, the stainless steel tube that should be retreated about 20 meters after the bright annealing furnace is opened will start to shine, which is the kind of bright reflection. Suzhou Jinrui electric furnace company as an electric furnace manufacturer, there are other series of electric furnaces, such as steel tube annealing furnace, stainless steel tube bright annealing furnace, etc., welcome to inquire!